Table of contents

High Efficiency Particulate Air or HEPA filters are used in air purification systems or industrial vacuum cleaners, among other devices. They effectively clean the air in factory, workshop or production facilities from dust and other emissions that can be harmful to health. The use of HEPA filters is a legal minimum standard in certain industries, for example sterile production. As such there are various HEPA filter classes. With the help of HEPA room air purifiers, even the finest particles, invisible to the human eye, are effectively removed and filtered out of the air.

In this guide you will learn about how they work, which HEPA filter classes are available for industrial vacuum cleaners, and how to clean HEPA filters.

HEPA filter classes for industrial vacuum cleaners

In industrial vacuum cleaners not fitted with HEPA filters, the smallest particles such as pollen and other dust can be reintroduced into the environment via the exhaust and inhaled. By using a HEPA filter, the particles are retained inside the devices and clean air is expelled. Industrial vacuum cleaners with H13 and H14 HEPA filter classes are suitable for operating areas where, for example, toxic dust needs to be removed. As such, industrial vacuum cleaners contribute to improved indoor air.

Minimum Efficiency Reporting Values (MERV) ratings, determined by the American Society of Heating, Refrigeration, and Air-Conditioning Engineers (ASHRAE), are used to evaluate the efficiency of air filters, with MERV 17 being the level at which HEPA filtration is achieved. MERV ratings indicate the percentage chance that particles of certain sizes will be caught by the filter, providing a standardised way to compare different types of air filters. An air filter’s MERV is between one and 20, with the higher numbers being more efficient.

When choosing a vacuum cleaner, we recommend that you read the technical specifications of the manufacturer to find the correct HEPA filter classes. According to the British Standard: BS EN 1822-1:2019, HEPA filters are classified according to their collection efficiency. This is the ability to filter the finest particles.

The following table helps you to select your HEPA filter class requirements according to UK standards. This way you can know which filter is best for your industrial vacuum cleaner.

| Filter group | Filter class | MERV Rating | Separation efficiency (integral value in MPPS*) | Passage efficiency (integral value in MPPS*) | Separation efficiency (local value in MPPS*) |

|---|---|---|---|---|---|

| EPA: Efficient Particulate Air Filter | E10 E11 E12 | Merv 15 Merv 16 | ≥ 85 ≥ 95 ≥ 99.5 | ≤ 15 ≤ 5 ≤ 0.5 | – – – |

| HEPA: High Efficiency Air Filter | H13 H14 | Merv 17 Merv 18 | ≥ 99.95 ≥ 99.995 | ≤ 0.05 ≤ 0.005 | ≥ 99.75 ≥ 99.975 |

| ULPA: Ultra Low Penetration Air Filter | U15 U16 U17 | Merv 19 Merv 20 | ≥ 99.9995 ≥ 99.99995 ≥ 99.99995 | ≤ 0.0005 ≤ 0.00005 ≤ 0.000005 | ≥ 99.9975 ≥ 99.99975 ≥ 99.999975 |

With the help of a HEPA filter, even coronaviruses can be rendered harmless. For this, a particulate filter of at least class H13 quality is required – filters of lower classes cannot remove the viruses from the air. In addition, the units used require a high-volume flow depending on the room size.

Are HEPA filters washable?

If HEPA filters have been in use for a while, the filtered particles accumulate on the fabric fibres. This reduces the performance of the filter over time. Before washing a HEPA filter, be sure to read the manufacturer’s information. This is because for some HEPA filters, cleaning is not recommended and they should not be reused. Manufacturers must explicitly label this in the information provided.

Generally, a distinction is made between washable and non-washable HEPA filters. The washable variants are also suitable for wet-dry vacuum cleaners. Non-washable HEPA filters for single use, on the other hand, can be damaged even by a gentle cleaning process. Their ability to filter is thus significantly reduced after they have been cleaned.

However, even a washable HEPA filter that has been cleaned according to the instructions will not achieve 100% of the initial performance. After a HEPA filter is washed, dirt and particles may remain in the filter fabric and can reduce its performance. In short, even if you clean a HEPA filter, you will have to replace it after a certain period of use – depending on the level of use.

How to clean HEPA filters

We recommend the following five points when HEPA filter cleaning:

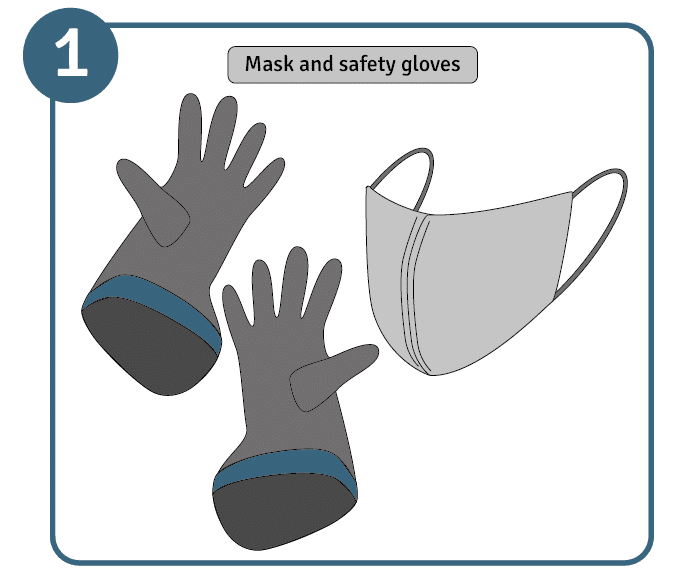

- Protect yourself from particles

Before you start, ensure you protect yourself from particles. To remain safe and prevent the inhalation of microscopic, airborne particles during the cleaning process, we recommend wearing a mask and gloves.

Before you start, ensure you protect yourself from particles. To remain safe and prevent the inhalation of microscopic, airborne particles during the cleaning process, we recommend wearing a mask and gloves. - Preliminary cleaning

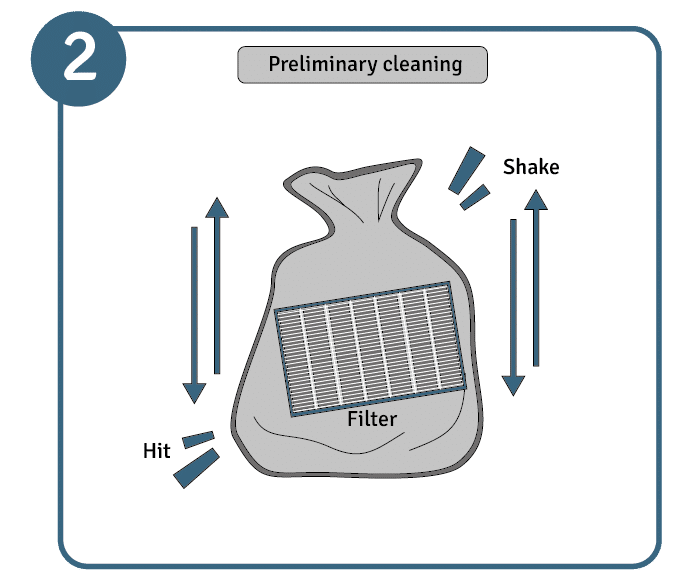

At the beginning of the cleaning process, seal the HEPA filter in a plastic bag to avoid inhaling the particles trapped in it. Now free the separator from coarse dirt and particles using shaking or tapping movements. If possible, carry out this entire process outdoors.

At the beginning of the cleaning process, seal the HEPA filter in a plastic bag to avoid inhaling the particles trapped in it. Now free the separator from coarse dirt and particles using shaking or tapping movements. If possible, carry out this entire process outdoors. - Preparation

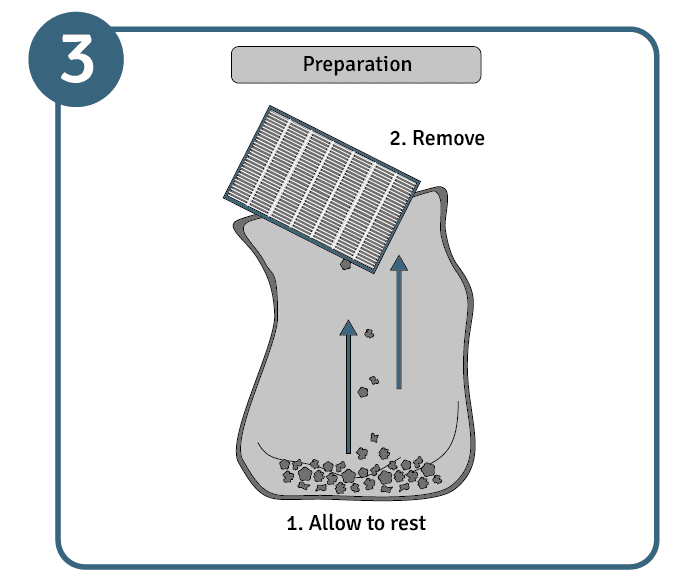

In the next step, leave the filter in the bag for a while until the shaken particles have settled. Then you should carefully remove the filter so as not to stir up the dust again.

In the next step, leave the filter in the bag for a while until the shaken particles have settled. Then you should carefully remove the filter so as not to stir up the dust again. - Washing the HEPA Filter

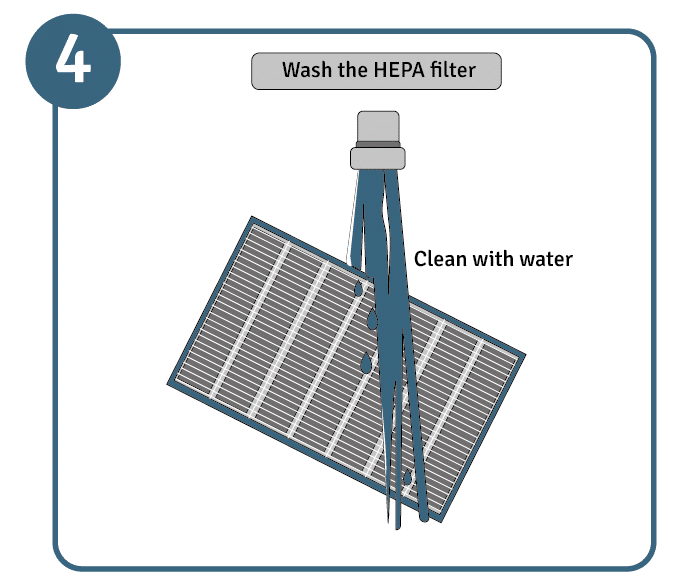

Next, rinse the filter under running water. Be sure to follow the manufacturer’s instructions before using cleaning agents. You should also use tools such as brushes with care so as not to damage the HEPA filter. Wash the HEPA filter carefully.

Next, rinse the filter under running water. Be sure to follow the manufacturer’s instructions before using cleaning agents. You should also use tools such as brushes with care so as not to damage the HEPA filter. Wash the HEPA filter carefully. - Dry

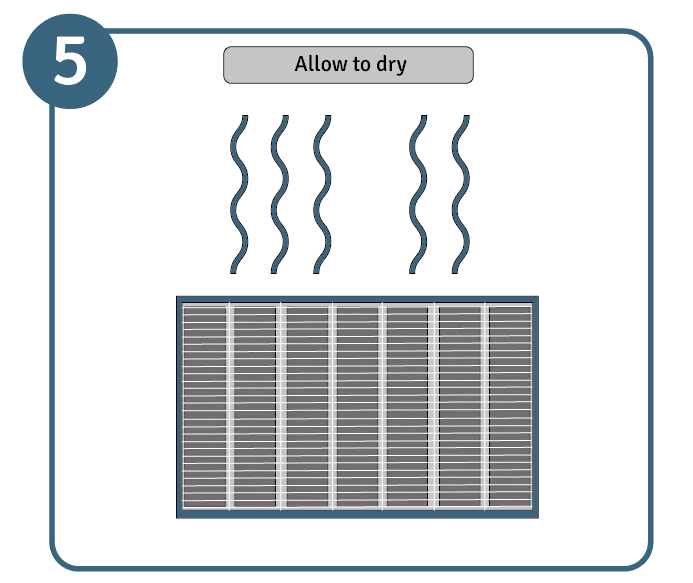

The last step is to carefully dry the filter. Make sure that it is completely dry before using it again. This is because residual moisture forms an ideal basis for mould.

The last step is to carefully dry the filter. Make sure that it is completely dry before using it again. This is because residual moisture forms an ideal basis for mould.

Function and structure of HEPA filters

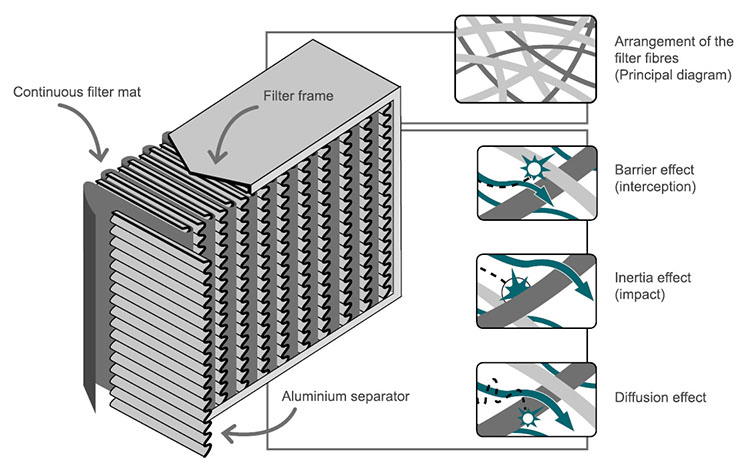

Basically, a HEPA filter consists of a very fine-meshed and multi-layered fabric made of cellulose, glass or synthetic fibres and materials of various thicknesses. These filter mats are arranged in layers and kept apart by corrugated separators. The entire filter is enclosed in a stable frame.

The effectiveness of HEPA filters is based on a combination of various physical and mechanical factors:

Due to the multi-layer structure, coarse particles cannot pass through the fabric structure of the filter because of the so-called sieve effect. This is why, for example, different types of dust are separated.

For particles up to 0.7 µm, the inertia effect is exploited. Theoretically, they would be large enough to pass through the fine mesh. However, they are too sluggish to be guided past the fibres by the air flow. Therefore, the particles stick to them.

The barrier effect causes microns as small as 0.2 µm to be attracted to the mesh fibres due to their gravitational pull. For this reason, they also remain in the filter.

Microparticles smaller than 0.1 µm follow the diffusion effect. They move in random patterns independently of the airflow. That is why they easily collide with the tissue and stick to it. An example of this is allergy-causing mite faeces.

This complex system allows HEPA filters to capture up to 99.995% of all dust and airborne particles from the ambient air. Even respirable substances such as asbestos and mould spores can be filtered in this way.

Which occupational safety guidelines apply to HEPA filters?

The Workplace exposure limits (EH40/2005) regulations define which occupational exposure limits apply to different substances and particles in the UK. This is intended to contribute to occupational safety when dealing with airborne particles and the use of HEPA filters, among other things.

The specified regulations cover all necessary air-purifying measures for companies, industry, and workshops, for example for wood and concrete construction. Detailed information on the handling of individual substances, such as in wood dust or asbestos, can be found in a list of occupational exposure limits.

FAQ for HEPA filters and HEPA filter classes

Not all HEPA filters are washable or recyclable. There are variants for which cleaning is feasible and those that are only suitable for single use. Be sure to follow the manufacturer’s instructions when considering how to clean a HEPA filter. Manufacturers are obliged to state whether the product is suitable for multiple use.

When it comes to how to clean a HEPA filter, it is best to wash them outdoors. Always wear a mask and gloves to protect yourself from inhaling particles. Do not use cleaning agents or sharp objects to clean the HEPA filter as the material can easily be damaged.

For protection against coronaviruses, you need a device that is equipped with at least a class H13 HEPA filter. HEPA filter classes below this level do not provide protection against viruses.

Please note: The regulations mentioned above represent only a selection of the most important legal requirements. Please refer to the listed organisations and directives for more detailed information. If in any doubt, consult experts or contact the relevant regulatory authorities.

Image source:

© gettyimages.de – sturti